Precision Manufacturing

In different sectors such as Medical, Automotive and Aerospace, the necessity of using Complex parts is increasing due to engineering studies and special designs in line with the needs and intended use of the sector.

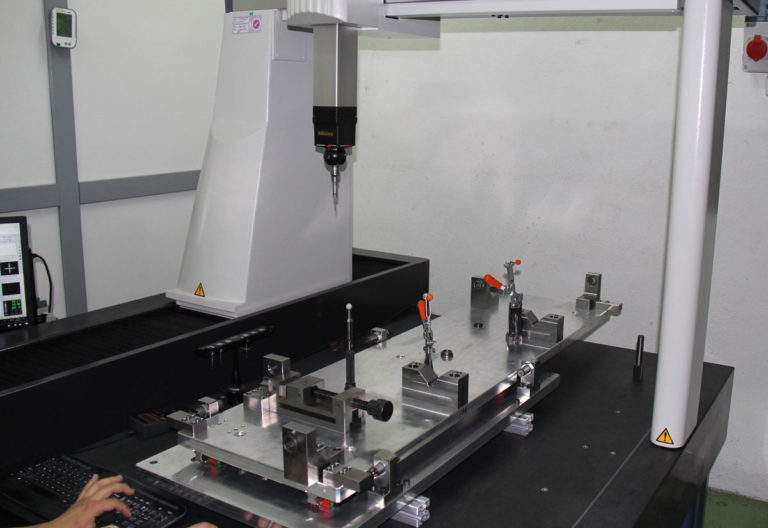

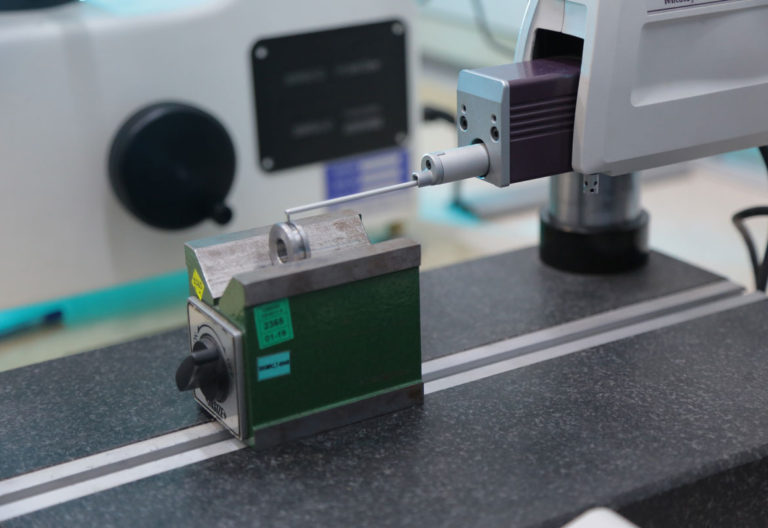

In this context, BKM Teknoloji has a PRECISION MANUFACTURING capability that can produce products with high Dimensional, Geometric and Surface quality precision by using its machine and device infrastructure for Multi-Axis Machining, Grinding and Polishing operations for complex parts manufacturing.